Solar&Wind Hybrid Division of Sunlaite

is integrated independent R&D design, manufacturing, sales and application project solution into one piece.

Currently, the division just got the key techniques with independent technical Intellectual Property about 13 items,

and the advanced techniques and the superior project contract solution can guarantee the adaptability of all products to the application environment and case customization.

The main products of the division are including small vertical axis wind turbine, horizontal axis wind turbine, solar&wind hybrid street lamp system, Solar street light,solar&wind hybrid small power station,

off grid solar&wind hybrid turbine generator for home use, wind turbine generator system, Modular solar&wind hybrid power supply, small solar&wind hybrid distribution power station, solar&wind hybrid lighting/monitoring etc,

and the main market is including USA, Canada, Australia, UK, Europe,Indonesia, India and middle east etc.

History

After Sunlaite established in May of 2011, the Division was engaged in investigating about large area DSSC BIPV and demonstrated and constructed small pilot production line of large-area DSSC BIPV.

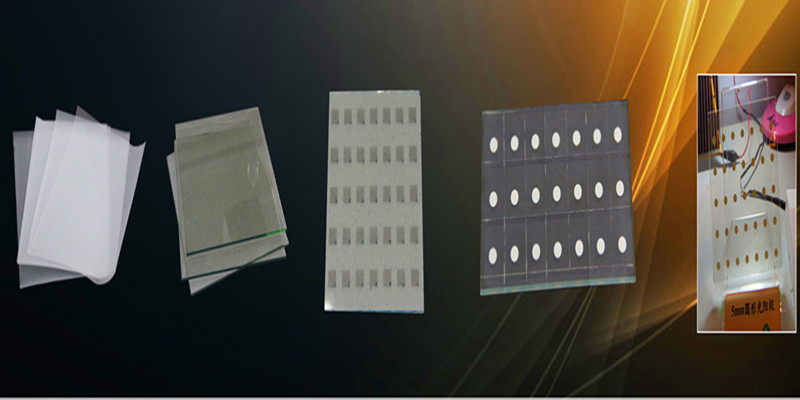

March of 2012, successfully manufacturing the first DSSC with the size of 100*100mm, the efficiency is about 2%.

Jan of 2013, New Solar Cell Division was established, mainly overtaking the development,pilot and BIPV application project of large-area DSSC core materials.

June of 2013, 100*100MM DSSC with 4.5% efficiency.

July of 2013,Independently assembling pilot production complete set of equipment with annual capacity 1MW large-area DSSC, 100*100mm DSSC 5% efficiency.

Aug of 2013, DSSC Joint Lab established with Taiwan Yongguang Chemical Group,integrating resource and having complementary advantages,developing together high efficiency large-area DSSC manufacturing technology.

Sept of 2013,Attending the Thirteenth China Photovoltaic Conference Forum,introducing large-area DSSC and its related core material and vacuum Filling Equipment.

Oct of 2013,Attending Chinano Forum together with Nanotechnology Exhibition, showing the sample of large-area DSSC and demonstration product, the large-area DSSC Technology got highly credits from the same industry.

Nov of 2013, Optimizing process,the efficiency of 4.9px2 can be up to 10.7%(the maximum efficiency in the world is 12%).

Dec of 2013, 100*100mm, efficiency 6%, 200*200mm DSSC, efficiency 5%,

March of 2014, DSSC Vehicle Sky Window confidentiality agreement signed through Taiwan Yongguang Chemicals, Nanjing University-Kunshan Innovation Research Institute, Kunshan Sunlaite Tech Company, Guangyue Computer Tech Company,

Yusheng Industrial Company, and start-up of DSSC application development just promoted the DSSC Tech R&D and industry application.

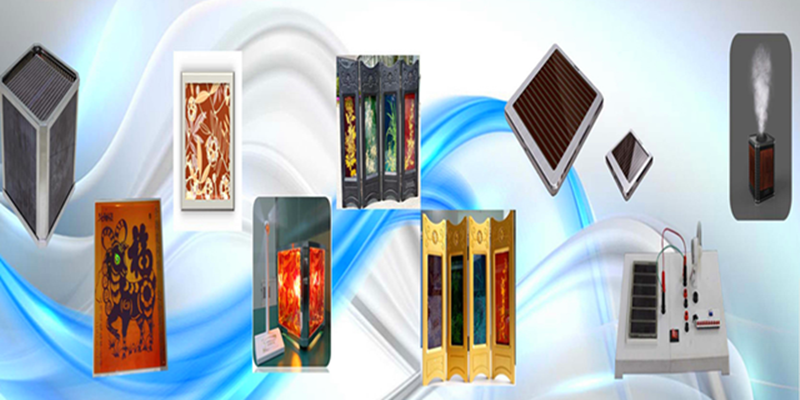

April of 2014, Meilan Bamboo and Chrysanthemum music screen was developed,and weak light effect is very remarkable.

July of 2014, Attending the Fourteenth National Solar Photochemical and Conference on Photo-catalysis, and exhibiting DSSC Pilot achievement and promoting the core material and DSSC Pilot technology.

Oct of 2014, Small-area efficiency after optimizing can be up to 10.2%, and its performance was close to brand material in the market.

Nov of 2014, Manufacturing the first BIPV curtain wall assembly based on DSSC Technology, light transmittance>30%, Power 50w/m2,.

Dec of 2014, 100*100mm, DSSC, 8% efficiency, 200*200mm DSSC, 7% efficiency.

May of 2015, Small-area efficiency of core material can be up to 11.8%,and its performance was better than general material.

Sept of 2015, Small Pivot of Perovskite Solar Cell was confirmed and building small pivot production line.

Nov of 2015,The efficiency of 2.25px2 Perovskite Solar Cell is 10%.

May of 2016, The efficiency of 2.25px2 Perovskite Solar Cell is 17%, and developing compact layer solution and MAI material.

Aug of 2016, Manufacturing 2.25px2 Pervoskite Solar Cell, and its efficiency was 18%, and starting developing Mesoporous Carbon-based printed cell,

Oct of 2016, the efficiency of 2.25px2 carbon-based Perovskite Solar Cell is 6.5%.

Nov of 2016, Manufacturing 2.25px2 Perovskite Cell, and its efficiency was 18.9%.

March of 2017,Manufacturing 2.25px2 Perovskite Cell with its performance 19.6%, and large-area carbon-based Perovskite Cell manufacturing technique is confirmed, and independently Researching Mesoporous printing paste.

May of 2017,Optimizing the performance of Printing paste,and the efficiency of 100*100mm large-area Perovskite is 7%.

Aug of 2017,The efficiency of 100*100mm Perovskite Cell is 9%, and efficiency of 200*150mm is 7%.

Sept of 2017, Successfully manufacturing the first 300*450mm Perovskite,after sealed, its efficiency is 4.8%.

April of 2018, The efficiency of 300*450mm large-area Perovskite Cell in half year working outdoors is 5%.

June of 2018, The efficiency of 300*450mm large-area Perovskite Cell is 7%.

Aug of 2018, The efficiency of 300*450mm Perovskite is keeping about 8%, and the efficiency of 10*250px Cell is 12.4%.

Nov of 2018, Developing Slit Coater manufacturing, and the efficiency of 300*450mm Cell is 10.47%.

Dec of 2018, 300*450mm Solar Cell working outdoors about 50 weeks, and cell efficiency attenuation is about 10% with good stability.

In 2019, Planning Mid-pivot production line of 10mw Perovskite Solar Cell through cell stability testing and technique optimizing ;